ATEX & IECEx Zone 1 Certified Hot Work Habitats

If you’re in the market for a solution to safely perform hot work operations in hazardous environments, you might be interested in learning about ATEX & IECEx Zone 1 Certified Hot Work Habitats. These portable, modular structures are designed to provide a safe workspace for personnel carrying out hot work activities in hazardous areas, such as those found in oil refineries, chemical plants, and offshore platforms.

key benefits to using safe zone your industry

Safeguarding People

HSEQ Compliance

Protecting Production

Preserving Assets

Reducing Shutdowns

Flexible & Modular

What is a Zone 1 SafeZone Habitat?

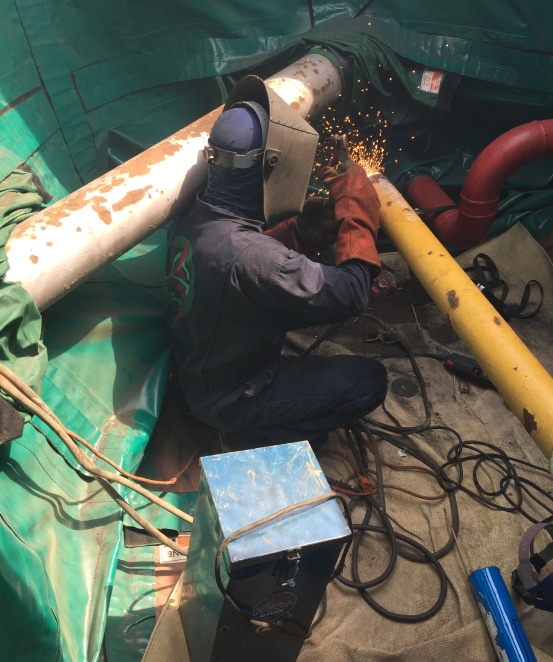

A Safe Zone Habitat enables hot work and maintenance to proceed without the need to shut down significant portions of a facility, resulting in cost savings. Our hot work habitats are used in various industries and locations, including offshore and onshore oil and gas installations, marine operations, refineries, chemical processing plants, distilleries, food manufacturing and processing factories, as well as utility and water treatment sites, to ensure safety and reduce expenses.

What is ATEX & IECEX?

ATEX and IECEx are international standards that are for equipment and protective systems intended for use in potentially explosive atmospheres. i.e Any location with the potential to cause an explosion.

ATEX is a set of European Union regulations that cover equipment and protective systems intended for use in potentially explosive atmospheres. It stands for “ATmosphere EXplosive” and it’s a framework of regulations put in place to ensure that equipment used in potentially explosive atmospheres is safe and will not cause an explosion.

IECEx is an international certification system for equipment used in explosive atmospheres. It stands for “IEC System for Certification to Standards Relating to Equipment for Use in Explosive Atmospheres” and is based on the International Electrotechnical Commission (IEC) standards. It provides a single certification scheme that is recognized globally and it’s similar to the ATEX.

Both ATEX and IECEx certify that equipment and protective systems intended for use in potentially explosive atmospheres have been designed, tested, and manufactured to strict safety standards, and that they have been independently verified to be safe for use in such environments.

As the operator of a facility you have a legal obligation to adhere to local laws and regulations. If your company operators within Europe you must adhere to ATEX

What is ATEX & IECEX?

Ensuring safety in potentially explosive environments like oil rigs, chemical plants, refineries & FPSOs is not only a legal requirement but its of ethical importance. Our habitat System works on two basic & key principles: containment of hotwork source and over pressurisation.

We manage containment by using a flexible flameproof panel arrangement that surrounds the working area, preventing the escape of sparks or welding slag.

This means that any potential ignition sources are contained within the designated area, eliminating the chance of a fire or explosion.

The panels are made of flameproof materials that can withstand extreme heat and are designed to prevent any sparks or slag from escaping the working area.

Over Pressurisation is the process of maintaining a controlled over-pressure within the habitat, providing a barrier against the ingress of hydrocarbons or other hazardous gases during operation. This is achieved by using our gas detection and over pressurisation system that maintains a positive pressure within the habitat, preventing any flammable gases or dusts from entering the working area.

By utilising both a spark containment approach and an over pressurisation approach, the risk of a fire or explosion is effectively controlled and the safety of the workers is significantly increased. We eliminate two sides of the fire triangle meaning its virtually impossible for a fire or explosion to start.

Talk to our team about Safe Zone Habitats

8am – 5pm GMT

Monday – Friday