ATEX & IECEX Hot Work Habitat – Providing Safe and Reliable Solutions for Hazardous Environments

When it comes to hazardous environments, safety is paramount. That’s why our ATEX & IECEX Habitat System is essential for companies looking to protect their employees. This system creates a safe zone for workers to operate in, shielding them from the dangers of potentially explosive atmospheres.

The Safe Zone Habitat System is a tried and tested solution that is approved by ATEX, IECEX, UCAS, and EAC for Zone 1 & Zone 2 Areas.

The Cunningham Safe Zone Pressurized Hotwork Habitat utilises advanced technology for exceptional performance, durability, reliability, and versatility in extreme environments. It is CE marked to the ATEX directive and IECEx certified for safe operation in potentially explosive gas atmospheres in Zones 1 and 2.

Features & Benefits of Safe Zone Habitats ATEX & IECEX Habitat

Safeguarding People

HSEQ Compliance

Protecting Production

Preserving Assets

Reducing Shutdowns

Flexible & Modular

What is a SafeZone Habitat?

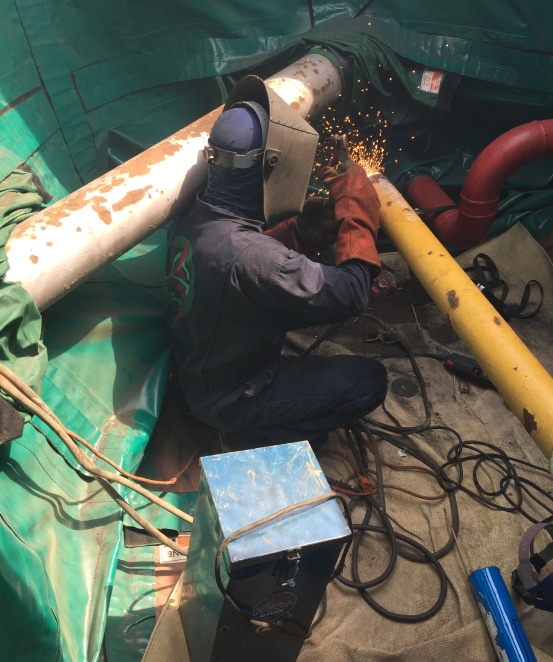

A Safe Zone Hotwork Habitat is an ATEX & IECEX Hotwork Habitat which is an approved welding habitat system suitable for Zone 1 & Zone 2 areas. These can also be called Welding habitats, Hotwork Habitats, Isolation Chambers, Safe Houses and Pressure Habitats and they create a safe zone for hot work in hazardous areas, without requiring production shutdown

Essentially Its a positive pressure enclosure (otherwise known as an isolation chamber) used to provide a safe work environment for performing hot work in the presence of explosive gases or vapours.

Our system is specifically designed for use in areas with explosive atmospheres, such as oil and gas facilities, chemical plants, FPSOs, and drilling rigs. It is compliant with ATEX and IECEx standards, ensuring it meets safety and performance requirements.

Constructed from durable and robust materials, our habitat system is built to withstand harsh conditions from the North Sea to the blistering heat in the Middle East. It is fully portable, inflatable, and reusable, and is one of the few engineered controls suitable for hotwork. We meet all HSEQ requirements around the world.

What is ATEX & IECEX?

ATEX and IECEx are standards that are for equipment and protective systems intended for use in potentially explosive atmospheres. i.e Any location with the potential to cause an explosion.

ATEX is a set of European Union regulations that cover equipment and protective systems intended for use in potentially explosive atmospheres. It stands for “ATmosphere EXplosive” and it’s a framework of regulations put in place to ensure that equipment used in potentially explosive atmospheres is safe and will not cause an explosion.

IECEx is an international certification system for equipment used in explosive atmospheres. It stands for “IEC System for Certification to Standards Relating to Equipment for Use in Explosive Atmospheres” and is based on the International Electrotechnical Commission (IEC) standards. It provides a single certification scheme that is recognized globally and it’s similar to the ATEX.

Both ATEX and IECEx certify that equipment and protective systems intended for use in potentially explosive atmospheres have been designed, tested, and manufactured to strict safety standards, and that they have been independently verified to be safe for use in such environments.

As the operator of a facility you have a legal obligation to adhere to local laws and regulations. If your company operators within Europe you must adhere to ATEX

SPECIFICATIONS

- ATEX and IECEx certified for use in Zones 1 and Zones 2

- No Extra Axillary Equipment needed (All Safety Systems Included)

- Flammable Gas Detection Detection

- Automatic Welding Shutdown on Gas Detection (Included as Standard)

- Automatic Air Shut off on Detection outside the habitat

- Audio and Visual Alarms on Units

- Enhanced Entry Control System

- Gas Detection & Visual Alarm for Inside Habitat

- Built in Safety Systems and PLCs

| PRODUCT DESCRIPTION | Safe Zone Pressurised Habitat & Gas Detection & Shutdown System * |

| OPERATING TEMPERATURE | -20 + 50 °C |

| TYPE OF PROTECTION | px |

| AREA OF CLASSIFICATION (GAS) | Zones 1 and 2 Gas Groups IIB / IIC |

| TEMP. CLASSIFICATION (GAS) | T4 |

| CERTIFICATES | See downloads for latest certification. |

| INGRESS PROTECTION (GAS DETECTION / WELDING SHUTDOWN) | IP66 |

| PLUG OPTIONS (GAS DETECTION / WELDING SHUTDOWN) | CEAG, STAHL, APPLETON, ATX Others can be fitted on Request. |

| GAS DETECTION RANGE (GAS DETECTION / WELDING SHUTDOWN) | 0-100% LEL Methane 0-50ppm H2S |

| ALARM LEVELS (GAS DETECTION / WELDING SHUTDOWN) | 10% LEL CH4 5ppm H2S Other Gases & Levels etc can be configured on request to meet site requirements. |

| FREQUENCY OF EQUIPMENT (GAS DETECTION / WELDING SHUTDOWN) | 50/60hz |

| GAS DETECTION / SHUTDOWN SYSTEM | 600 x 1120 x 585 (W x L x H) |

| POWER OPTIONS (GAS DETECTION / WELDING SHUTDOWN) | 110 / 220V – 380 / 576V 16, 32, 64 AMP options available All will depend on supply onsite, welding equipment or heat treatment equipment being used. |

All information has been gathered under laboratory conditions, the user must regard the values given as approximate.

Changes may be made to the above specification without notification, details are available on request.

HOW DOES IT WORK?

A reliable process safety management framework is essential for efficient facility operations. Our pressurized hot work habitats are certified for ATEX & IECEX and adhere to HSEQ guidelines for hierarchy of controls. They provide effective engineering measures to manage and reduce risks during hot work activities. Our Safe Zone System is a unique Engineering Control that can be used for risk reduction.

With 50 years of industry experience, our Safe Zone hot work habitats have established themselves as a dependable and cost-efficient approach to risk reduction and compliance with industry standards.

The Safe Zone positive pressure welding habitat is a key component of a fully certified ATEX & IECEX system and control measure. It facilitates hot work tasks in hazardous environments, including those classified as zone 1 and 2, H2s & Hydrogen Environments.

Our Safe Zone System addresses risks through two fundamental properties:

- Encapsulation: The adaptable flame-resistant panel configuration encloses the work area, effectively containing sparks or welding slag.

- Pressurization: The regulated overpressure within the habitat establishes a barrier that prevents the entry of hydrocarbons or other dangerous gases during operation.

Our complete Certified Customizable Hot Work Habitat System offers versatile modular zip configuration and design. It enables Safe Zone Pressurized habitats to be installed in any required dimensions and form, integrating effortlessly with obstructions such as structural beams and pipework. This guarantees that regardless of the worksite location, our habitats can be effortlessly set up.

We provide a safe and comfortable way to perform welding. The air moves quickly, and there’s a system to remove harmful fumes, making it ideal for hot work.

Talk to our team about Safe Zone Habitats

8am – 5pm GMT

Monday – Friday